Programmable logic controllers are electronic devices that are frequently used in the management of industrial processes.

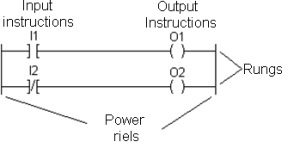

They were introduced in the 60s to replace the former wire logics or relay logics, which were made with different kinds of relay (such as general propose relay or timer), in fact the first PLC instructions emulate relay functions and were arranged in a graphics language called ladder, by its similarity to a ladder as used by firefighters, very similar to diagrams and plans of the relay logic.

The programmable logic controllers have evolved with the technology, now have an instructions set that include logical functions, arithmetic functions, comparison functions, file functions, program flow functions and PID functions among others.

Features programmable logic controllers

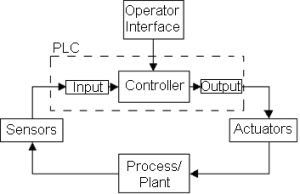

The in fact the first PLC instructions emulate relay functions and were arranged in a graphics language called ladder have at least four basic parts: the controller or CPU (central processing unit), the power supply that supplies electric energy to the devices, the input modules that connect the input devices to the PLC, and the output modules that connect the PLC to output devices. If all the parts are on equipment, the PLC is called fixed otherwise; all the parts are put together in a chassis, these PLCs are called modular.

The goal of a PLC is to keep a process in a desired state, for it must know the process current state, this is done by connecting some sensors to input modules, also it must know the desired state, typically an operator provides it by an operator interface. If the current state is different to desired state, the PLC computes a control action carried out by actuators connected to the output modules.

To programming the programmable logic controllers are used a language. The IEC61131 standard specifies four languages, these are: ladder, function block, structured text and instruction list. Also includes the special function charts, which is a structure of programming similar to Grafcet that allow organizing the routines, where each action is designed with any of the four languages mentioned above.

The present day it talk about Programmable Automation Controllers, which have all functions of the PLC, but also are very versatile to control motion, drives, integration of networks and distributed control systems (DCS).